Decisions about Shacman dump truck dimensions are safest when you treat them as a verification process, not just a single spec number. At HOWO Special Truck Ltd, we help buyers get trucks that fit the real-world constraints of roads, ports, and job sites.

Shacman trucks are often considered for heavy-duty tipping work. However, a dimension mismatch can create delays that horsepower can’t fix. A truck may be correct for payload but fail to fit through a site gate, under a hopper, or in a dumping zone with overhead lines.

This article explains what “dimensions” mean for procurement and how to confirm the exact build you are ordering. The goal is to help you prevent surprises between the quotation, shipment, and the first day of operation.

Table of Contents

Key Dimensions for Shacman Dump Trucks

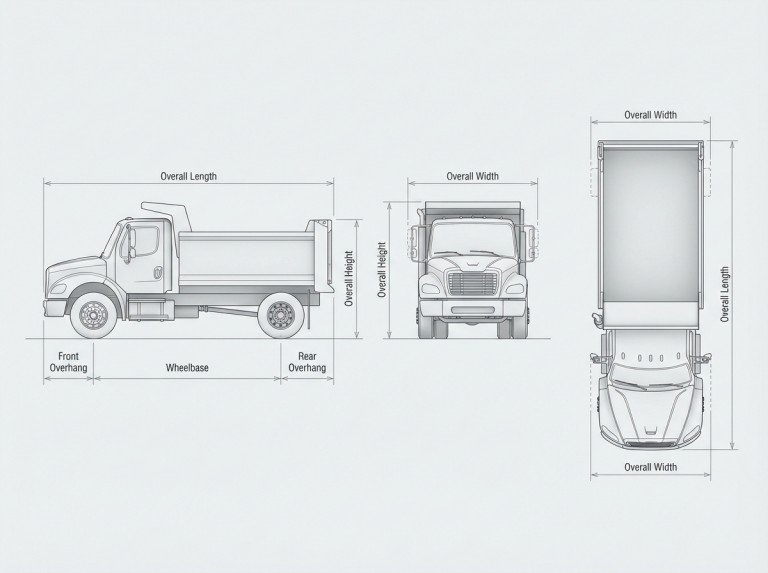

Shacman dump truck dimensions become reliable only when the buyer and supplier use the same measurement points and configuration. Many disputes start because one party quotes a chassis drawing while the other assumes a body drawing. Sometimes, “overall height” changes with the cab roof and tire choice.

Overall dimensions define the outer envelope that interacts with roads, gates, and loading equipment. Body dimensions describe the dump box space and dumping geometry, which relate to excavators, hoppers, and stockpiles.

Wheelbase and overhangs are crucial when site access is tight. These numbers control maneuvering space, how the truck handles ramps, and how it positions under a loader.

The best way to align on scope is to name each dimension and state how it’s confirmed. Use the table below as a shared checklist during the quotation and order stages.

Dimension to Confirm | Why It Matters in Operations | How to Measure It on the Truck | Where to Confirm It Before Shipment |

|---|---|---|---|

Overall length (OAL) | Gate fit, ramp approach, turning space planning | Front-most point to rear-most point | General arrangement (GA) drawing and final build sheet |

Overall width (OAW) | Road use, narrow access, hopper lane fit | Widest outside point, including mirrors and add-ons | Body and chassis drawings, plus add-on list |

Overall height (OAH) | Hopper clearance, bridge clearance, workshop entry | Ground to highest fixed point with the chosen cab | Cab spec, tire spec, and GA drawing |

Wheelbase | Turning behavior, positioning, ramp transitions | Centerline of front axle to centerline of rear axle group | Chassis spec sheet and axle layout drawing |

Front/rear overhang | Approach and departure issues, bumper clearance | Axle centerline to nearest end point | GA drawing and chassis layout |

Dump body internal size | Payload volume planning and material flow | Inside length, width, and height of the box | Body drawing with “internal” clearly labeled |

Dump body external size | Clearance under hoppers and structures | Outside length, width, and height of the box | Body drawing with “external” clearly labeled |

Raised dump height | Overhead clearance and safe dumping zone setup | Ground to highest point at full tip, plus rear reach | Body lifting geometry drawing |

If your Shacman dump truck quote doesn’t show the measurement basis, treat the number as a placeholder. We recommend asking for a marked drawing so the reference points are clear.

Common Mistakes When Reading Dimension Specs

Most dimension problems come from misreading the spec sheet, not from unusual Shacman designs. The same model name can ship with different wheelbases, cabs, tires, and dump bodies, each changing the final size.

A common mistake is confusing the dump body’s internal dimensions with the truck’s overall size. Another is assuming the listed width is the maximum width, while mirrors or steps extend further.

The table below shows practical issues we see during verification. Each item includes a prevention step you can use when reviewing a quote.

Mistake Pattern | Typical Consequence | What to Verify | Prevention Action |

|---|---|---|---|

Internal box size read as overall size | Truck doesn’t fit under hopper or through gate | Both internal and external box dimensions, plus overall width | Require drawings labeled “internal” and “external” |

Cab height is assumed “standard” | Clearance failure in sheds, mines, or tunnels | Cab roof type, air deflectors, intake/exhaust routing | Confirm overall height with the exact cab option |

Tire choice is ignored | Height and width shift from the assumed baseline | Tire size, rim spec, and axle track width | Lock tire spec in the purchase order |

Add-ons excluded from “overall” numbers | Mirrors or guards cause contact in narrow routes | External add-ons list and installation positions | Ask for an “as-built envelope” note on the GA drawing |

Raised dump height is not checked | Overhead cable strike risk during tipping | Full-tip geometry and maximum raised height | Require lifting geometry and plan a safe dumping zone |

Wheelbase selected only for payload | Tight turns and loader positioning become difficult | Wheelbase options and site turning space constraints | Decide wheelbase using site layout, not just capacity |

You can prevent these mistakes when your RFQ includes measurement definitions. A simple one-page verification package is often enough to align the supplier, shipping team, and site supervisor.

Main Shacman Dump Truck Configurations

Shacman dump truck dimensions change predictably based on axle configuration and duty scenario. A 6×4 and an 8×4 are not just different capacities; they imply different chassis lengths, wheelbase patterns, and space needs.

Published specs for a road-legal 6×4 often show an overall length in the mid-8-meter range. An 8×4 build typically extends to the 10-11 meter range. Treat these figures as estimates until the exact configuration is confirmed on a GA drawing.

Road-legal widths are commonly listed around 2,500 mm. However, the “real widest point” depends on equipment and add-ons. Off-road wide-body mining trucks can exceed 3,000 mm in width and often require special transport planning.

Further reading: Are Shacman dump trucks suitable for heavy-duty mining?

6×4 On-Road Construction Setup

A 6×4 configuration is a good choice when maneuverability is as important as box volume. The shorter chassis can reduce the space needed to position under an excavator or navigate a tight site. While these trucks usually fit standard road envelopes, the dump body height still affects loading and dumping clearance. If your site has short ramps or sharp turns, a 6×4 layout is often easier to fit into a constrained workflow.

8×4 Heavy-Duty Site Setup

An 8×4 configuration is common for high-production projects where larger bodies and higher trip efficiency are valuable. The added axle layout increases the chassis length and the turning space required at loading and dumping points. The main risk is not straight-line hauling but the turning needed to keep the loader productive. For 8×4 builds, it’s very important to confirm wheelbase and overhangs, as small changes can affect ramp behavior.

Off-Road Wide-Body Mining Setup

Off-road wide-body mining trucks prioritize stability and ground clearance over road rules. These changes often increase overall width and height, making normal highway movement impractical. The decision for these trucks is as much about transport logistics as it is about the machine itself. Your verification should include the widest points and the maximum operating height when dumping.

Further Reading:Which Shacman dump truck model is best

Key Factors That Change Shacman Dump Truck Dimensions

Shacman dump truck dimensions can vary a lot within the same series due to configuration choices. The best approach is to identify the options that change the external size and lock them in early. It helps to separate “chassis-driven” changes (wheelbase, cab height) from “body-driven” changes (box size, raised dump geometry).

Wheelbase and Overhang Choices

Wheelbase is the key variable that changes overall length and turning behavior. A shorter wheelbase can reduce the space needed for turns but may limit body length options. Front and rear overhangs affect how the truck handles ramps and uneven ground. To manage this risk, verify wheelbase and overhangs on a dimensioned side-view drawing.

Cab Roof, Deflectors, and Exhaust Layouts

Overall height is heavily influenced by the cab roof type and any equipment mounted above it. Air deflectors, intake routing, and exhaust stacks can all change the highest point. Height also depends on tire size and suspension. To avoid clearance failures, confirm the overall height with the exact cab and tire specifications in your order.

Tire Size, Track Width, and Add-Ons

Overall width should be the “widest as-built envelope,” not just the nominal chassis width. Tire size and track width can change the truck’s stance, and add-ons like steps or mirrors can become the true widest point. The easiest way to control this is to request a note on the GA drawing that states the widest point and the components that define it.

Dump Body Internal vs. External Size

Dump body dimensions must be split into internal (volume) and external (clearance) measurements. Internal size helps estimate usable volume, while external size determines fit under hoppers. Side wall height affects both loading reach and dumping stability. For clear dimension control, require the body drawing to label “internal” and “external” dimensions.

Dimension Verification Checklist for Your Order

A Shacman dump truck order remains predictable when the agreed dimensions are documented and attached to acceptance criteria before shipment. Shipping and site teams need dimensioned drawings, not just model names. We use a simple flow that moves from documents to physical site constraints, then back into the purchase order.

Dimension verification checklist:

- Request a general arrangement (GA) drawing showing overall length, width, and height.

- Request a chassis layout showing axle configuration, wheelbase, and overhangs.

- Request a dump body drawing that labels internal and external dimensions.

- Request the maximum raised height at full tip if overhead clearance is a concern.

- Confirm the tire size and cab roof type in the configuration summary.

- Confirm the widest point and which components define it.

- Write the confirmed dimensions and document IDs into the purchase order as acceptance criteria.

This checklist works best when you also measure your site. A gate width or hopper clearance is faster to measure than to debate after delivery.

How to Confirm the Exact Configuration

Your dimension request is most effective when tied to specific documents. Ask for a GA drawing, chassis layout, and body drawing that match the quoted configuration. Also, request a summary that lists the cab type, tire spec, axle configuration, and wheelbase.

How to Confirm Loading and Dumping Clearances

Loading clearance depends on the dump body side height and chassis height. Compare the loader bucket clearance to the external side height of the body. Dumping clearance depends on the maximum raised height. Treat overhead lines or canopies as hard limits. If there is any overhead risk, get the raised height value in writing.

How to Confirm Site Access and Maneuvering Space

Confirm gate fit using the widest as-built dimension, including mirrors. Ramp behavior depends on wheelbase and overhangs, so check those before the truck arrives. A steep ramp can cause contact. Check maneuvering space using your site’s tightest turn to ensure trucks can position without repeated adjustments.

How to Document Dimensions in the Order

Your order should state the agreed overall length, width, and height as verified on specific drawing revisions. Add an acceptance criterion that the shipped truck must match the stated configuration. If the configuration changes, update the dimension documents before shipment.

Conclusion

You can manage Shacman dump truck dimensions easily by defining measurement points and verifying the exact configuration before shipment. Align on terms, confirm the drawings match the build, and then check those numbers against your site constraints.

When you treat dimensions as a documented acceptance item, you reduce the risk of clearance failures and workflow bottlenecks. This approach ties your purchase decision to real operating conditions, not just generic specs.

FAQ

What is the typical overall width for road-legal Shacman dump trucks?

Many road-legal Shacman dump trucks are listed with an overall width around 2,500 mm. However, the as-built widest point, including mirrors and steps, should be verified. Confirm this on a GA drawing that matches the final configuration.

How do I tell if a quoted dump body size is internal or external?

A quoted dump body size is only clear when the drawing labels it as “internal” or “external.” Internal dimensions describe usable space, while external dimensions affect clearance. Always require a drawing that labels both.

What dimension most often causes site access problems?

Wheelbase often causes issues with turning in tight sites, but overhead clearance failures can be more severe. Wheelbase affects how trucks position under a loader. Height becomes critical when loading under hoppers or dumping near power lines. Both should be verified against your site.

What documents should confirm dimensions before shipment?

Final dimensions should be confirmed by a general arrangement drawing, a chassis layout, and a dump body drawing. The configuration summary should state the axle layout, wheelbase, tire size, and cab option. The purchase order should reference these documents.

How do I confirm dumping clearance with overhead lines?

Confirm the maximum raised height at full tip for the selected body. Use that value to design a dumping zone with a clear overhead margin. If the supplier cannot provide this value, the risk should be considered unresolved until verified.