HOWO fuel tanker truck play a key role in oil transport. They ensure efficient, safe, and eco-friendly transport. To keep them running smoothly, it’s important to know and fix common issues.

These issues include brake, clutch, tire failures, and tank leaks. Regular checks and repairs by drivers and maintenance teams are crucial. They help keep the truck in top shape. Drivers should also follow traffic rules and drive carefully.

Regular maintenance and inspections are key to avoiding these problems. They help in ensuring efficient, safe, and green oil transport.

Table of Contents

Overview of Common HOWO Tanker Truck Failures

Common failures in HOWO tanker trucks include tank leaks and corrosion. They also include problems with control systems, oil and gas recovery systems, and engines. Tank leaks are often due to aging or damage to the tank seals.

It’s important to replace seals and regularly inspect and maintain the tank. We should check for tank corrosion and ensure the anti-corrosion coating is intact. We need to repair or replace seriously corroded parts.

To improve corrosion resistance, we should choose the right anti-corrosion materials. We need to check if the tanker’s temperature control and pressure monitoring system is working. We may need to calibrate or replace faulty parts.

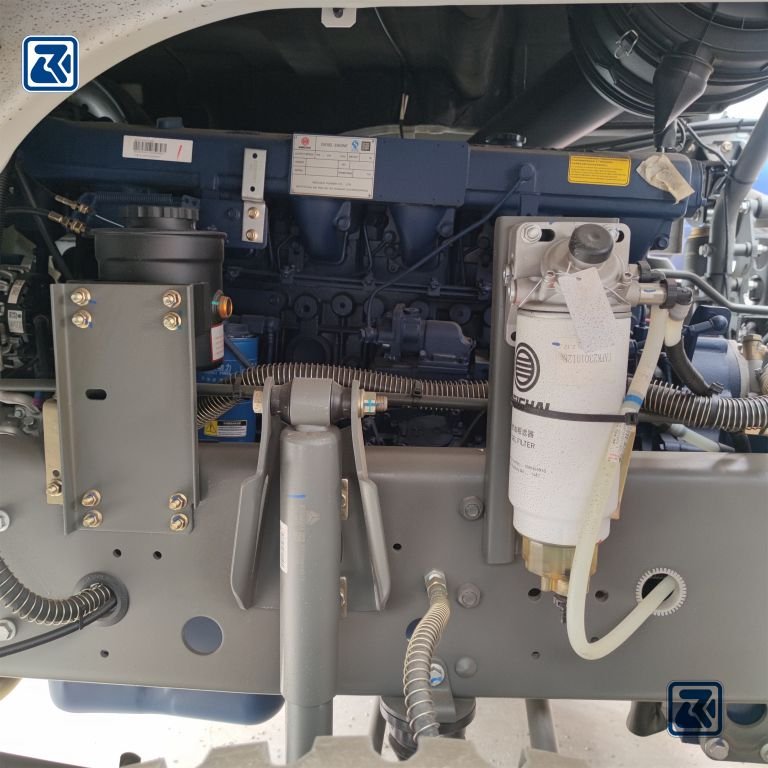

Failure of the oil and gas recovery system needs quick pipeline clearing. We should regularly inspect and maintain the equipment. This minimizes environmental impact. Engines need regular maintenance and inspection.

This includes changing oil, checking spark plugs, and cleaning air filters. These steps ensure stable engine operation.

Engine Failures and Solutions

Engine failure is common in vehicles. Different types need different fixes. Difficulty starting is usually caused by a low battery, faulty ignition system, or fuel system problems.

Solutions include checking and replacing the battery. Also, cleaning or replacing the spark plugs and ignition coil. And, checking the fuel pump and fuel filter. Finally, removing air from the fuel system.

Lack of power can be caused by a clogged air filter, fuel system problem, or ignition system problem. Solutions include replacing or cleaning the air filter. Also, inspect the fuel pump and fuel filter. Clean or replace them as needed. And replace worn or damaged spark plugs and ignition coils.

Rattles are usually caused by worn engine parts, poor lubrication, or cooling system problems. Solutions include inspecting and replacing worn parts. Also, changing the oil to ensure lubrication. And, checking the water pump and coolant to ensure the cooling system works.

Hydraulic System Failures and Solutions

Hydraulic system failures can have a serious impact on the normal operation of the equipment. Leaking hydraulic oil is usually caused by bad seals on oil pipes or fittings, seal failure of hydraulic components, or bad seals on the hydraulic tank.

The fix includes regular inspection of oil pipes, fittings, and seals on hydraulic components. This is to ensure that all joints are tight. Also, we must repair or replace very worn parts. Low system pressure may be due to pump wear, clogged oil lines, or pressure valve failure.

To fix it, check the pump and oil lines, clean clogged filters and oil lines, adjust or replace the pressure valve, and test the system for low pressure. Failure to operate is usually caused by control system failure or actuator failure.

The fix includes checking if the electrical system is connected correctly. Also, check that the sensors and solenoid valves work properly. Then, check for stagnation or wear inside the cylinders and motors. Finally, do any needed cleaning or replacement. For detailed information, please see How to maintain the hydraulic system of HOWO tanker truck.

Oil Tank Leakage and Solutions

Tank leaks are a common but extremely dangerous problem in the petrochemical industry. Tank wall corrosion is usually caused by the environment, defects in manufacturing, or poor maintenance.

Solutions include inspecting tank walls for corrosion. Also, applying anti-corrosion coatings slows corrosion. Lastly, repairing or replacing severely corroded parts. Poor seals are usually caused by deterioration of sealing materials, improper installation, or environmental factors.

Solutions include three things. They are regular inspection of tank seals, replacing damaged seals, and tightening loose fasteners. Pipe ruptures are usually caused by age and wear, corrosion, or design defects.

Solutions include regular corrosion inspections and pressure tests. You also must repair or replace pipes that are severely worn or pose a safety hazard.

Brake System Failures and Solutions

Brake system failures can significantly affect driving safety. Brake failure is usually caused by insufficient brake fluid, deteriorated brake fluid, or worn brake pads or discs.

Solutions include checking and topping up the brake fluid. Also, replacing brake fluid to keep it clean and working. And, swapping out old brake pads and discs. Poor braking is usually caused by brake leaks, dirty pads or discs, or air in the system.

The fix includes fixing the leaks, cleaning the pads and discs, and removing the air to restore normal braking. Brake noise is usually caused by worn brake pads, uneven disc surfaces, or foreign objects in the braking system.

Solutions include putting in new brake pads and discs. Also, check the braking system often and remove any foreign objects in it.

Electrical System Failures and Solutions

Electrical system failures are common in cars, machinery, and appliances. Low batteries are usually caused by long periods of inactivity, leaks in the electrical system, or improper use.

Solutions include charging the battery with a charger. Also, checking for leaks in the electrical system and fixing them. And using electrical appliances appropriately to cut unnecessary use and frequent startups.

Short circuit is usually caused by aging, improper installation or poor contact of electrical components. The solution includes replacing aging or damaged wiring, plugs, and sockets, professionally repairing poor contact problems, and ensuring that electrical components are reliably connected.

Lights don’t come on often. This is caused by bad bulbs, wiring problems, or bad switches or relays. Solutions include checking bulbs and replacing them if needed. Also, check the wiring for damage and fix it. Replace bad switches or relays.

Body and chassis faults and solutions

The body and chassis are key to a vehicle’s stability and safety. Body rust comes from the environment and poor care. To stop rust, clean the body with a mild detergent, apply a rust inhibitor, and fix any rust spots.

Chassis loosening is often due to loose parts or damage. Regularly check and tighten fasteners. Replace them if needed. Also, fix any damage from accidents.

Suspension system damage comes from wear and tear, overload, or neglect. To fix it, inspect the system often. Keep parts well-lubricated. Replace worn parts and seek help for complex issues.

Conclusion

Knowing how to handle common faults in HOWO tanker trucks is crucial. It ensures safety, efficiency, and protects the environment. Any malfunction can be dangerous, especially when carrying dangerous liquids.

By understanding and fixing these issues, we can avoid accidents. Regular maintenance and quick fixes extend the vehicle’s life. They also save time and money, improving efficiency and reducing environmental harm.

For technicians and operators, mastering these skills is vital. It enhances their abilities and emergency response. This is key for their careers and personal growth.

HOWO Special Truck Ltd. offers a wide range of services. They provide expert advice and support in vehicle selection and use. They offer maintenance, parts, and technical support.

FAQ

Common engine problems include hard starting and a lack of power. You might also hear strange noises, see high temperatures, or notice odd emissions. Oil leaks and electrical issues are also common. If you’re unsure, it’s best to get help from a professional.

When the hydraulic system has a problem, shut it down and disconnect the hydraulic source. Check for malfunctions using diagnostic tools. Refer to system manuals for repair or maintenance. Then, perform tests and verifications. Record summaries and do professional inspections to ensure safety.

To prevent tank leaks, focus on design and materials. Regular inspections and maintenance are also crucial. Train staff in safety and leak prevention. Protect the environment and be ready for emergencies. Avoid sparks and metal friction to prevent damage.

HOWO Special Truck Ltd. offers full support from the start. They help choose the right model and provide maintenance, parts, and technical support. They ensure customers get ongoing help to keep their vehicles in top condition.